If there’s ever going to be a nationwide hydrogen economic system, we’re going to want to alter just a few issues. Considered one of them is how we produce hydrogen itself, the overwhelming majority of which comes from fossil fuels. SunGreenH2 brings a nanotech-level advance to green hydrogen production, supercharging electrolysis so orders of magnitude extra hydrogen might be cleanly made straight from water.

Hydrogen is in use far and wide, however the lack of a scalable, green choice for producing it has slowed its adoption. What’s the purpose of getting a hydrogen battery system for renewables if you must supply that hydrogen from pure fuel, oil and coal?

The reply is the method of electrolysis, which separates water molecules into their constituent atoms, producing hydrogen and oxygen. Sounds nice, however it takes loads of power and costly parts like platinum to supply the catalysts and membranes that make up the tech sandwich of any fashionable electrolyzer cell. So green hydrogen is a number of occasions costlier than soiled hydrogen and more durable to make besides.

In comes SunGreenH2, which has made a serious enchancment to an important a part of these cells: the electrode. The corporate claims that it could double hydrogen production, decrease the price and cut back reliance on platinum and different uncommon parts multi function swoop.

“We’re nanostructuring a proprietary alloy-based electrode that dramatically will increase the floor space accessible for the response,” mentioned CEO and co-founder Tulika Raj. “For a given measurement of lively space, [it] ends in enhancement of present density (straight associated to hydrogen production) by greater than double. However that’s not sufficient, you must to be scalable and manufacturable. So it doesn’t use treasured metals — on this case we’re decreasing the quantity wanted by 30x.”

She mentioned that virtually all fashionable electrolyzers can use this improved electrode. “The thought is to carry your entire trade,” she mentioned.

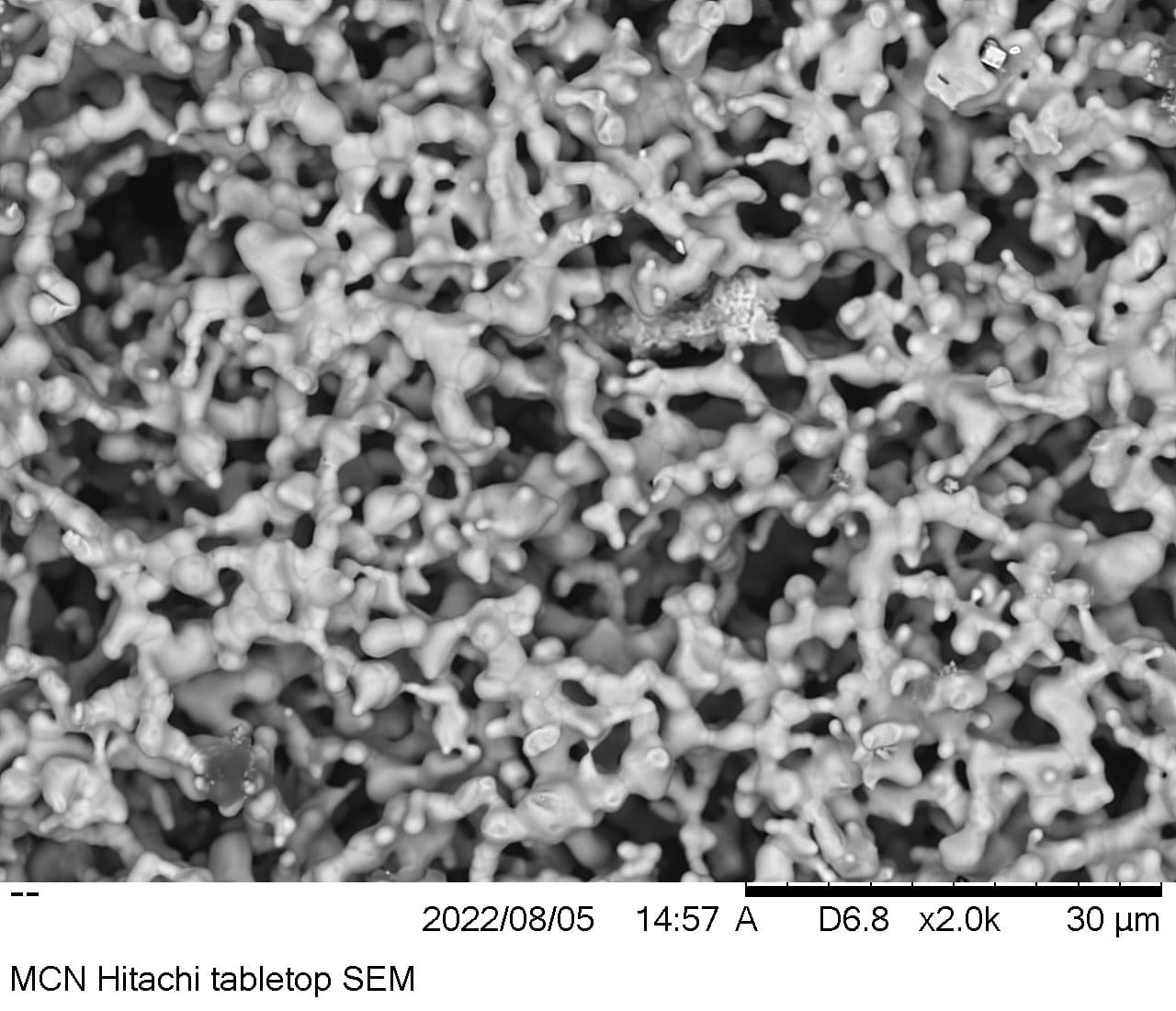

The nanostructure floor is the first advance, and you may see a scanning electron microscope picture of it right here:

Picture Credit: SunGreenH2

It appears to be like a bit chaotic, however the materials is fastidiously engineered to work together with the opposite chemical parts of the electrolysis course of (primarily water and a catalyst), and by forming a form of 3D sponge construction reasonably than a flat or tough one, it doubles the floor space that response can occur on.

One weak spot of nanostructures is that they’re very fragile and vulnerable to degradation, decreasing their effectiveness (nonetheless miraculous) over time. SunGreenH2 has gotten out forward of this flaw with “the novel idea of sacrificing catalyst.”

“Growing the floor space and tuning the crystallinity of the deposited supplies ends in enchancment of the efficiency and stability, respectively, whereas utilizing the sacrificing catalyst ends in vital enhancement of the lifespan of the principle catalyst,” Raj defined. “In present/present know-how, as a result of corrosion of the catalyst, the efficiency of the electrode reduces. Within the know-how developed by SunGreenH2, corrosion of the sacrificing catalyst ends in enhancement of the floor space, which compensates for the affect of corrosion.”

SunGreenH2 co-founders Tulika Raj (left) and Saeid Masudy Panah. At proper, a prototype electrolysis stack with the corporate’s tech within the center someplace. Picture Credit: SunGreenH2

In different phrases, this second materials pervades the construction, and its corrosion course of (in some way past my understanding) retains the principle catalytic floor contemporary.

The corporate has raised a $2 million seed spherical led by SGInnovate, with participation from Vinci BV, Cap Vista, Entrepreneur First, SOSV’s HAX, she1K and Apsara Investments. Raj mentioned that this cash will go to establishing their first manufacturing amenities in Melbourne to satisfy the calls for of their early companions, that are confidential however embody main power considerations within the EU, U.S. Canada, Japan and Singapore.

Although the intention at first is to promote the electrode element individually, subsequent 12 months it plans to associate with system integrators to supply entire electrolysis stacks and finally with bigger firms to supply extra end-to-end options. “We will additionally apply our platform know-how to manufacture comparable green transition supplies, i.e., electrodes, PTLs and bipolar plates for gasoline cells, electrodes for batteries and photoelectrodes for direct photo voltaic to hydrogen panels,” Raj mentioned.

All that depends upon their success in these early days, but when a green hydrogen revolution goes to occur, the trade should begin embracing applied sciences like this one sooner reasonably than later.